robot end effector pdf

1guide frame 2gompression rollers 3connection reels 4motors for. End effectors are.

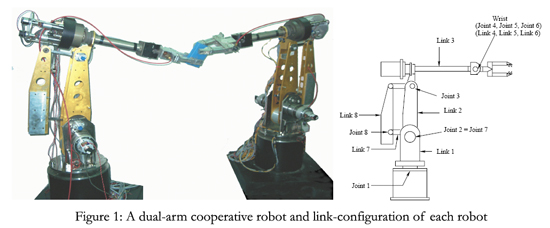

Jrm Vol 27 P 496 2015 Fuji Technology Press Academic Journal Publisher

In a wider sense an end effector is the part of a robot that interacts with the work environment.

. This paper describes a capstone design project in developing an end -effector for robotic arm that is capable of grasping objects of varying sizes. This activity demonstates how an end effector is constructed to resemble a human hand. All the components that are being chosen for the end effector need to be configured onto the robot anticipating that everything was done correctly the first time.

One of applications of industrial robots is spot welding in which Odes constitute the end effector of the robot. Download Full PDF Package. 11 for the identification of unstructured parts and anonymous environment in industrial robot.

Have students think of a job that an end effector could do and design an end effector for the job. Design Of A Robotic Arm With Gripper End Effector For Keywords. A short summary of this paper.

Appropriate end effector for. Whatever the cause the consequences involve possible damage to the end effector or maybe even the robot itself. Multifunctional End Effectors for Robotic Surgery Mary Frecker PhD and Alan J.

Other aPplications in which tools are used as end effectors include dc welding. This does not refer to the wheels of a mobile robot nor the feet of a humanoid robot which are not end-effectors because they are part of the robots mobility. End-effector sensing on the robot structure and its control.

Diagrammatic Sketch of the Pruning Robots End Effector a b Fig. The end effector was redeployed on February 24 1999 and used to scan visible construction defects on the side of the tank. The effects might be classified into three categories.

The next design phase of an end effector is to look at how the robot will move with this tool and if it needs an offset or angle bracket to make it easier to move in the operating space. Base that attaches to the robot the clamp axis the shuttle axis the frame and pressure foot the nosepieces and the process tools. 10182015 C 2001 Ernest L.

End effector motion is controlled by a Fanuc 18i series CNC. The center point of end -effector should remain as close as possible to the same location ie. A robotic end-effector integrated with multiple sensors was developed by O.

A typical payload-to-weight ratio of a robot arm is about 120. Full PDF Package Download Full PDF Package. 2 each symbol is expressed as.

This activity demonstates how an end effector is constructed to resemble a human hand. The task was to design an end effector. This presents the need for an accurate real-time full state estimation of the robot end-effector including velocity and acceleration.

Each sub-assembly performs a unique task essential to the performance of the system. The End-effector One of the most amazing designs of the International Space Station is its robotic arm or End-effector a device mechanism at the end of the arm used to grab space objects. Human-Robot Interface for end effectors 161 4.

The end-effector may be holding a tool or the end-effector itself may be a tool. A perspective view of the experimental proto-type end-effector that has the basic functional charac-. It is assumed that the sensor can detect the end-effector location and can guide it to the required location.

Be able to compute the load. Design Of A Robotic Arm With Gripper End Effector For Author. By definition an end effector is the device at the end of a robotic arm that allows it to interact with its environment.

When referring to robotic end. This is why each manufacturing robot needs an end effector. The end effector is like a mechanical hand with a cylinder 332 centimeters 1307 in in diameter by 258 centimeters 1016 in deep.

Of course an alternative means to release the sack material from the end-effector is to sepa-rate the rollers from one another G G G H G Figure 3. Overload Protection When some unexpected event happens to the end effector such as a part becoming stuck in a die or a tool caught in a moving conveyor. System of the driveline All actuators are connected to the active joints by the Nylon-Kevlar wire.

ROBOTEND EFFECTOR INTERFACE Physical support during the work cycle 3. The word End-effector means the last link or endpoint of the robot. A The Front View b The Top View.

An end effector is a kind of tool holder which is placed at the end of a robot. Design of a robotic arm with gripper end effector for Created Date. The end effector did not detect the defects and the operators saved three scans in an electronic file for later analysis by the OSS engineers.

A straight -line path over the range of gripper motion. The part of the robotic arm that grabs objects is called an end effector This wire-snare device is designed to fit over special grapple fixtures knobbed pins on the Shuttle ISS and ISS modules. The robot uses the end-effector to accomplish a task.

Hall University of Cincinnati 5. At this endpoint tools for the robot are attached and consist of a gripper or. Their undoubted advantage is a low friction coefficient and high tensile strength that is the ratio.

Grabbed by the rollers will come out of end-effector and the sack will be released. When a robot is unable to meet the position andor velocity accuracy necessary for applications such as these it is necessary to use real-time sensor feedback to guide the end-effector throughout the process. The design parameters are as follows.

Section 5-4 discusses the various end effectors was mentioned above that grippers are sometimes 1. Tools Grippers are end effectors used to. The robot uses the end-effector to accomplish a task.

The end effector in this case should hold a drill as well as a sensor. Snyder PhD S urgical robots are designed. However a robot arm alone can hardly accomplish any job.

ONCE end effector Clamp Axis. In this eBook you will find information on the different end effectors available on the market. ONCE end effector Figure 3.

The same kind of tendons are used to transfer the force from the active joints to the passive ones. Manipulator electronic hardware and software. End effectors may consist of a gripper or a tool.

After analysis the OSS. Have students think of a job that an end effector could do and design an end effector for the job. The end-effector may be holding a tool or the end-effector itself may be a tool.

The drill that would be used in this project was a Desoutter CFD 1155398 which is a manual drill meant to be held by hand and not by a robot. 37 Full PDFs related to this paper. The CAD Chart Involving the End Effector from Robot Used for Pruning Branches of Fruit Trees.

A Reconfigurable Robotic End Effector For Machining And Part Handling Machine Tool Simulation Semantic Scholar

Pdf A Double Claw Robotic End Effector Design Semantic Scholar

Robot End Effector Market Type Robot Type Application 2021 2030

Integrated Robotics Keba Comau Pdf Catalogs Technical Documentation Brochure

Pdf Comparison Of Exoskeleton Robots And End Effector Robots On Training Methods And Gait Biomechanics Semantic Scholar

Robot End Effector Definition And Examples

Robot End Effector Market Forecast To Grow To 6 5 Billion By 2025

Practical Use Of End Effectors Onrobot

Robot Arm 4 Bar Linkage End Effector Robot Gripper 11037 Robotpark Academy Robot Gripper Robot Arm Robot Design

Robot End Effector Definition And Examples

Pdf Robotics 1 Lecture 7 End Effectors

Pdf A Double Claw Robotic End Effector Design Semantic Scholar

Development And Analysis Of Reconfigurable Robotic End Effector For Machining And Part Handling

Pdf End Effector For Fast Wire Cutting And Crimping On A 4dof Parallel Robot

Pdf Development Of Robotic End Effector Using Sensors For Part Recognition And Grasping